voltage: 380V3P50Hz

power(w): 16.5kw

dimension(l*w*h): 3300*1100*1200mm

inlet diameter: 6.5mm

outlet diameter: 2.9mm

warranty: 1 Year

core components: Gearbox, Gear, Bearing, Engine, Motor, PLC

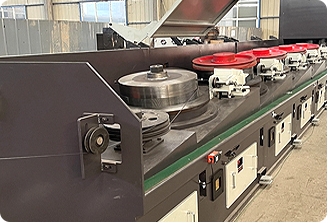

It consists of main gearbox, mould box, road wheel frame, wire starting frame and electrical control system.

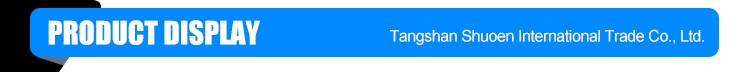

Each drawing reel is driven by the motor through the gear coupling secondary different speed ratio of

cylindrical gear deceleration, so as to make the reel rotating work, drawing reel for the vertical, mounted

on the cover of the box, gears are used to lubricate the oil immersion. The inner wall of the reel is equipped

with cooling water jets to reduce the residual heat on the surface of the steel wire channel line reel after

drawing, and the drawing mould is immersed in cooling water to reduce the working temperature of the mould.

To provide you withvarious equipmentmodels ,

specialcustomer service toarrange ustomizationfor you.

◆ Customization of body color

◆ Custom modification of equipment configuration

The production efficiency is 2-3 times that of

pulley wire drawing machine.

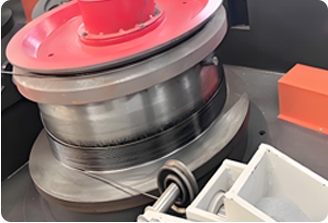

The drum of drawing machine adopts narrow

slotwater cooling, which has good cooling effect.

Andit is not easy to enter the dust The drum is sprayed

with tungsten carbide coating , can be used forten years.

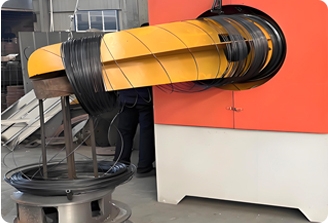

Applicable to a wide range of scenarios: steelwire,

stainless steel wire, copper wire, aluminum wire, etc.

Many take-up methods can realize directproduction or secondary

processing annealingafter finished products.

Q: How could find the most suitable machine?

A: Tell us your request in details: inlet wire and out wire diameter range, production capacity.

Q: Why should I choose your products?

A: ♦Quality & Price is built on each transaction's satisfaction customized design reasonable equipment

based on your request, our team's hard research & existing project.

♦Strict QC Inspection---8-Level quality assurance system off the production line details & video sent to

help your workers know how the device works OEM&ODM service with professional R&D and design team.

♦Maintenance response in 24 hours after-sales service team oversea technical support experience customer

reviews satisfaction is nearly 100%.

Q: Can your company send your engineers to my country for machine installation, worker training?

A: Yes, our engineers went to more than 60 countries before. They are very experienced.