Machine Type: panel fence welding machine`

Wire diameter: 2.5-6mm

Mesh width: 1-3M

Mesh length: 0.8-3.5m

Welding Speed: 80 times/min

Mesh size: 50*100/50*75mm

Voltage: 380/50HZ /Customzied

Weight: 4T

Warranty: 1 Year

Video outgoing-inspection: Provided

After Warranty Service: Video technical support, Online support, Field maintenance

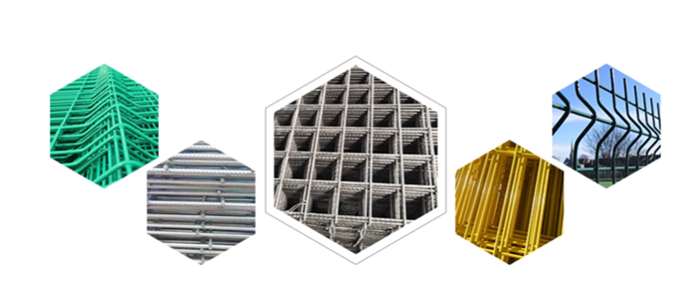

Welded mesh panel machine can produce road fence, beside that can produce kinds of reinforce

mesh for road, building, brige, coalmine,and so on, also can produce cage to feeding animal.

![]()

You can send your requirement to us, we can design the machine as you wish!

| Type1 | Type2 | Type3 | |

| mesh size | 50*50--200*200mm | 100*100--300*300mm | 100*100--300*300mm |

| width | 2000mm | 2000mm | 2000mm |

| motor | 5.5KW | 5.5kw | 5.5kw |

| transformer | 120KVA*4 | 160KVA*4 | 200KVA*4 |

| speed | 60rows/min | 50 rows/min | 40 rows/min |

| spare machine | wire straighten and cutting machine(2.5-6mm,two sets), | wire straighten and cutting machine(4-8mm two sets), | wire straighten and cutting machine(8-12mm two sets), |

1)Main welding machine:Speed:100times/min.Our welding machine adopts pneumatic pressure system ,

which ensure the welding points more firm than mechanical system.

2) Our line wire feeding is from pre-cut,as so the finished mesh panel surface will be more flat than ling

wire feeding from coil.And the line wire length can reach max 4.5m

3) The cross hopper with a cross wire storage and automatic feeding device, storage capacity of about

1.5 tons, to reduce the manual reclaim material, improve production efficiency.The pushing power adopts

1.0KW servo motor.

4) The pulling system power is droven by the servo motor.The pulling system adopts the circle model, which

save the time and improve the welding speed.Another advantage is the pulling frame is moved, and it is

more convenient when the line wire spacing is adjusted.

![]()

3D fence mesh purposes:mainly used in industrial,agricultural,prison,municipal,transportation and

other industries for fences,decoration,protection and other facilities.

![]()

- 1.Nude,with waterproof cloth and stow-wood.Imported computer control system packed with waterproof cloth and card board.

- 2.This producing line is maintained free of charge for 12 months.When the machine is used in China,we will install and debug

the machine for free;if it is used at abroad,we will send the professional technician to debug.Buyers should take all the fees for

technicians travelling abroad.

- 3.All the parts in the roll forming machine is free to maintain all the life,if in 24 months our company bear the cost for exchanged

the broken part like the new parts cost and express cost,if more than 24 month,we also free to maintain the broken parts ,but for

send the new parts,the buyer need bear the express cost.

- 4.When ship the roll forming machine,We will also send one set CD and specification(Chinese and English) to you with the

machine,they can teach you how to operater the machines.

· Company Profile

![]()

We, Tangshan Shuoen is a professional cold roll forming machine manufacturer, We have been focusing on this field for 10 years. Our equipment includes roof roll forming machine, floor deck roll forming machine, automatic decoiler, light keel roll forming machine, purlin machine, leveling and slitting machine, and other related construction equipment.Shuoen has employed a team of engineers for more than 10 years. At the same time, our machines use branded electrical components, raw materials from branded steel factories, strict process control, two-year warranty, installation and training services.Our customers are all over the world, such as 65 countries in Mexico, Chile, Bolivia, Italy, Australia, Kuwait, Saudi Arabia, South Korea, South Africa, Kenya and other different regions. We have extensive experience in the needs of different countries, such as profile, thickness range, use, installation, etc.Thank you for your trust and choice, we will provide you with the best service support and help you achieve greater success.Looking forward to more cooperation with new and old friends from all over the world.

Q1. How long is your warranty period?

Within 12 months from the date of self loading, we guarantee that no malfunctions will occur due to manufacturing defects.

Q2. How can I trust the machine to paste and test before shipment?

We have recorded a test video for your reference. Alternatively we welcome you to visit our factory and personally test the machines.

Q3: If you can customized the roofing sheet forming machine for i need?

Yes, Just share your design to us is ok, we will give you one fully quotations.

Q4: What's your after-sales service ?

We provide 24-hour online service for our customers.

And we are happy to give advice and also have skilled technicians available to maintain the machine overseas to customers' workshop if needed.

Q5: What's your delivery time ?

Normally we can finish production and testing within 45-70 days after receiving deposit. Some machines in stock, can be delivered at any time.