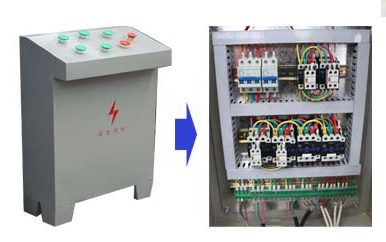

1.This machine is equipped with PLC control system,

so it is easy to operate this machine .

2.Adopt Japan Omron and France Schneider brand switches to assure

brick machine stable running.

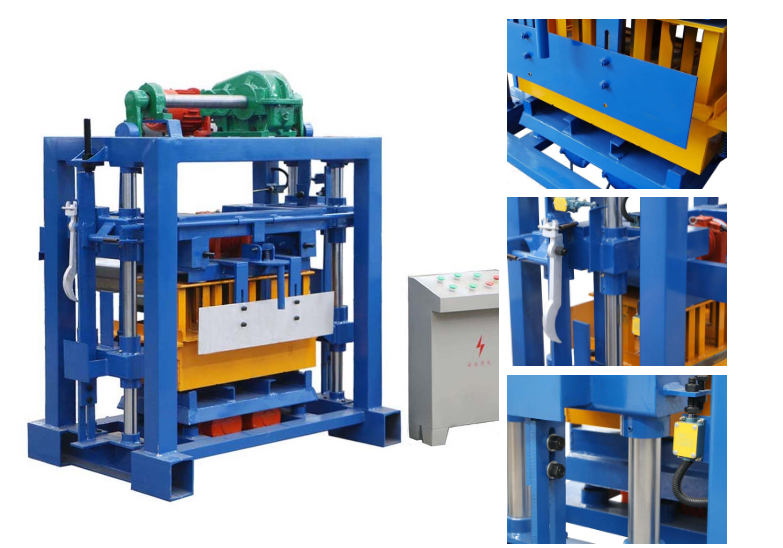

Type: Mobile Block Making Machine

Brick Raw Material: concrete,cement,sand,crushed stone,fly ash

Production Capacity (Pieces/8 hours): 800 pcs/8hours

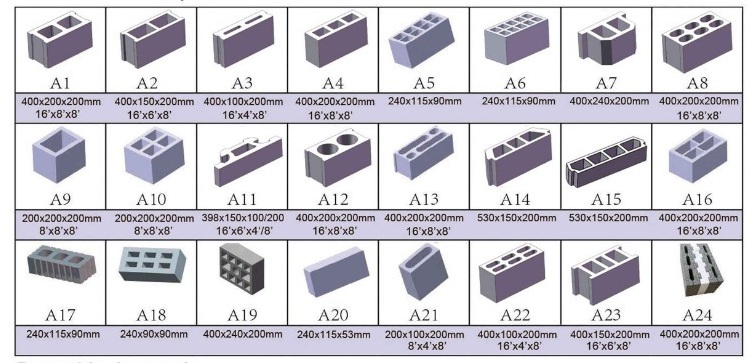

Brick size: 400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, Other

Dimension(L*W*H): 1800*1400*1100mm

Processing: Brick Production Line

Method: Hydraulic pressure

Weight (KG): 800 kg

Warranty: 1 years

Our machine has a long service life, simple operation and easy to use, we provide network

after-sales service for life. A strong behind-the-scenes team makes your purchase worry-free.

![]()

Techinical Parameter of block making machines

| Dimension of host machine | 920x800x1260 |

| Moulding area | 1025×810mm |

| Host machine power | 4.8KW |

| Vibration force | 100KN |

| Moulding period | 40-50s |

| The size of the pallet | 1350×900×30mm |

| General water Consumption | 12T/every day |

| Weight of the host machine | 14T |

production Capacity of block making machines

Material proportion of block making machines

1. 8-10% cement, 30-40 % sand , 50-60% crushed stone.

2. 8-10% cement, 30% flyash, 60% sand or stone powder.

Summary of Block machine Summary

1. Low price, saving cost, simple and fast installation, after six months of investment and operation, business

can be profitable, best choice for small and medium factories.

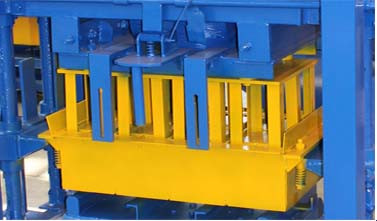

3. Can meet different production requirements by changing mould, we provide various mould for hollow bricks,

solid bricks, paving bricks, curbstones and etc, brick size and shape can be customized.

![]()

Easy Operation

1.This machine is equipped with PLC control system,

so it is easy to operate this machine .

2.Adopt Japan Omron and France Schneider brand switches to assure

brick machine stable running.

3.Precise line cutting technology and carburizing treatment to

prolong the life of the mould.

Materials

4.Steel we all use Q235-B which is not easily deform faded. You can check the quality

for this kind steel from the internet . And the thickness of steel plate we use on the

machine is 6mm

![]()

![]()

Selling Units:Single item

Package Type:seaworthy package

![]()

![]()

1.How about the quality of machines?

Our machines adopt advanced technology. Moreover, we carry out strict supervision during production and

make sure every finished product with high quality.

The advance deposit paid by T / T is 30%, and the balance before t / T loading is 70%. You can also choose other

trading methods.

Auto concrete brick making machine, Auto hydraulic brick making machine, Free pallet automatic block forming

machine,concrete,mixer, Batching machine, Stacker, Cuber, etc.