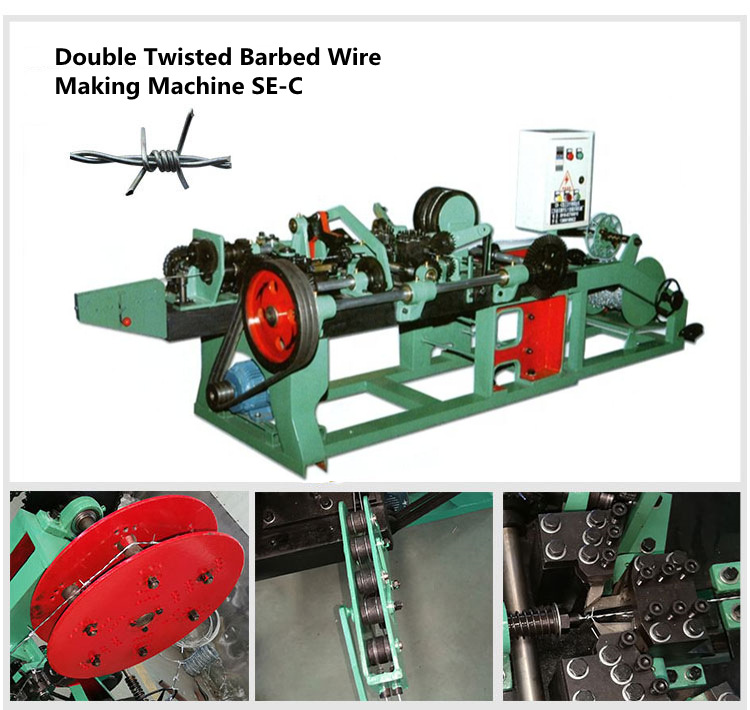

Machine Type: Barbed Wire Machine

Wire Diameter: 1.5-3 mm

Barbed space: 3-6inch

Barbed Wire Diameter: 1.6-2.8mm

Production Capacity: 40-70kgs/h

Power: 2.2kW

Weight: 1.2 ton

Warranty: 1 Year

Video outgoing-inspection: Provided

After Warranty Service: Video technical support, Online support, Field maintenance

Best price automatic barbed wire making machine

Twist Barbed Wire Machine provides a high tensile security barbed wire product. This machine can

produce up to six barb pitch sizes with production speeds up to 30m per minute. This equipment

was built using the most current technology and offers a high level of operator safety while

maximizing production rates and efficiencies for barbed wire manufacturers.

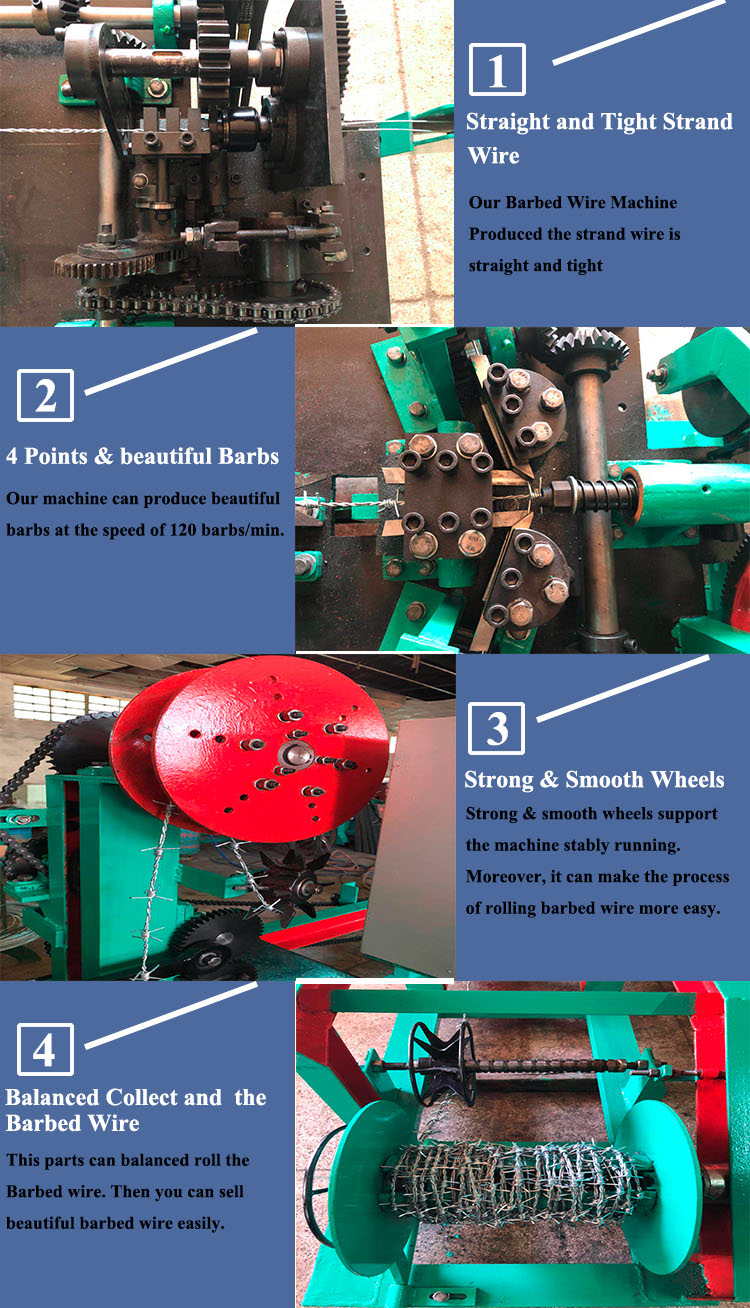

Advance Technologies

1. Manually installation, Easy to set up;

2. Steel cover on driving shaft for safety operation;

3. Saving materials and high capacity;

4. Counter to count the number of barbs and calculate length of barbed wire.

5. Button switches and leveler to start and stop machine easily.

6. Quick and easy roll extraction from the machine.

7. Guiding system to avoid wire snarls.

![]()

Items | SE-A | SE-B | SE-C |

Main wire Diameter | 1.5-3.0mm (Max.800MPA) | 2.0-3.0mm (Max.1700MPA) | 1.6-2.8mm (Max.1300MPA) |

Barbed wire diameter | 1.6-2.8mm (Max.700MPA) | 1.6-2.8mm (Max.700MPA) | 1.4-2.8mm (Max.700MPA) |

Barbed space | 3”, 4”, 5” | 4”, 5” | 4”, 5” |

Motor power | 2.2kw | 2.2kw | 2.2kw |

Twisted number | 3-5 | 7 | |

Raw material | Galvanized wire or PVC coated wire. | Galvanized wire | Galvanized wire |

Production | 70kg/h, 25 meters/minute | 40kg/h, 18 meters/minute | 50kg/h, 18 meters/minute |

Total weight | 1200KG | 1000KG | 1000KG |

Dimension | 1950×950×1300mm | 3100×1000×1150mm | 3100×1000×1150mm |

1760×550×760mm |

![]()

· Relative Raw Material

![]()

Barbed Wire Making Machine produces barbed wire, barbed wire widely used in military field, prisons, detention houses,

government buildings, national security facilities, and fencing of residences, villa wall and windows, express way, railway,

national border lines.

![]()

- 1.Nude,with waterproof cloth and stow-wood.Imported computer control system packed with waterproof cloth and card board.

- 2.This producing line is maintained free of charge for 12 months.When the machine is used in China,we will install and debug

the machine for free;if it is used at abroad,we will send the professional technician to debug.Buyers should take all the fees for

technicians travelling abroad.

- 3.All the parts in the roll forming machine is free to maintain all the life,if in 24 months our company bear the cost for exchanged

the broken part like the new parts cost and express cost,if more than 24 month,we also free to maintain the broken parts ,but for

send the new parts,the buyer need bear the express cost.

- 4.When ship the roll forming machine,We will also send one set CD and specification(Chinese and English) to you with the

machine,they can teach you how to operater the machines.

![]()

Q:What service can you provide before order?

A:About the pre-sale service, We provide professional solutions according your demands,such as design、

technical parameter, delivery flow etc. at the same time, we can supply invitation letter for your visit our factory

and know more our factory.

Q:Can you be responsible for transport?

A:Yes,we owned expert export team, we can arrangement for you to your destination port or address.

Q:Do you have after sales support?

A:Our engineer can supply remote-video technical support and teach your worker.

Q:How many workers is needed for the machine operation?

A:One worker is engough, the machine use automatic PLC control system.

Q:What's the warrany for our machine?

A:We provide 2years guarantee and provide lifetime technical support.

Q:If you can accept OEM? Design and manufacture according our photo.

A:Yes, we can accept OEM,we owned expert engineer team, and use famous brand components according

your demands.