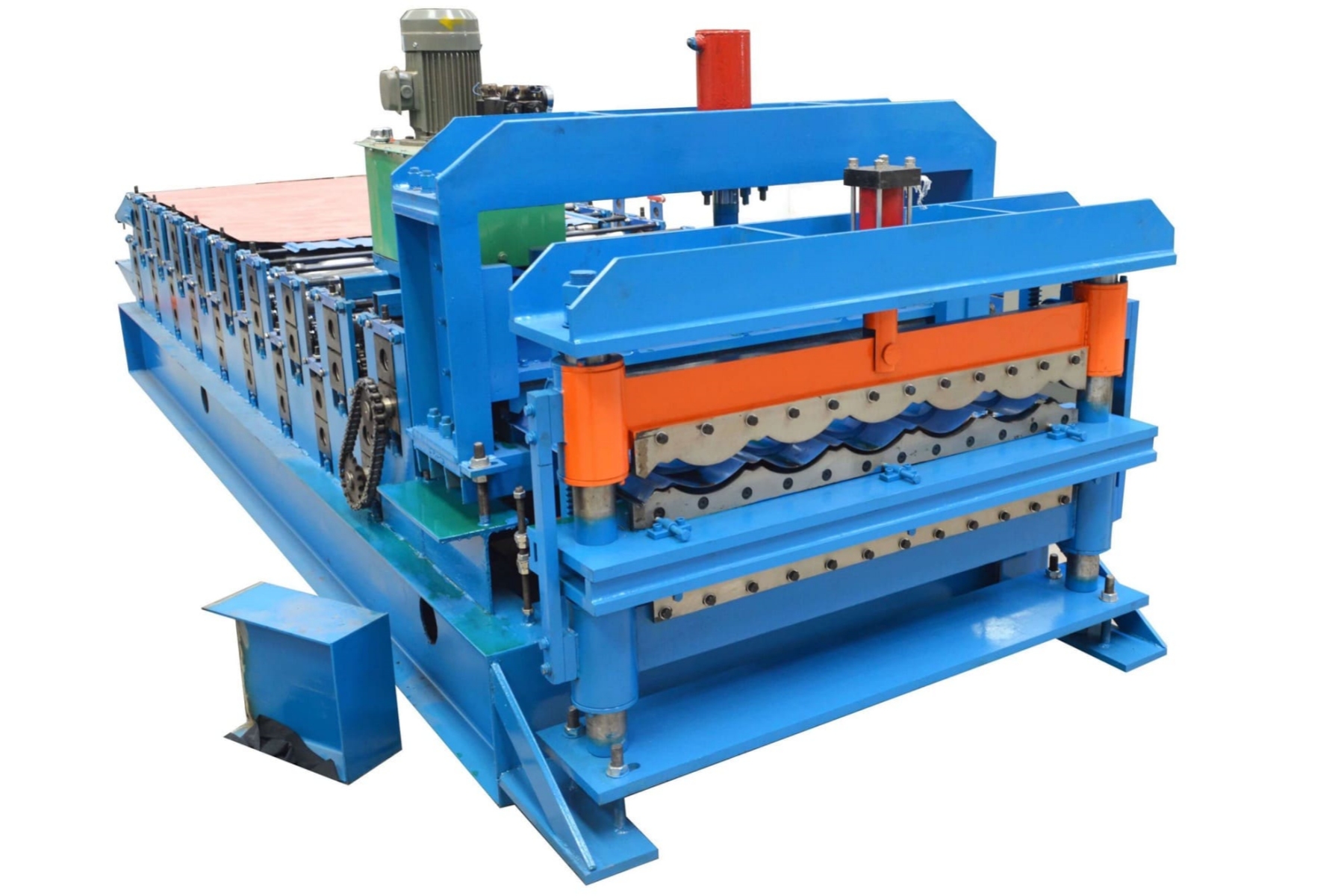

The tile press is a machine composed of discharging, forming, post-forming and cutting, its color plate appearance is smooth and beautiful, uniform paint grain, high strength, durable, widely used in industrial and civil buildings, such as factories, warehouses, gymnasiums, exhibition halls, theaters and other rooms and walls.

The components of the tile press include: the whole machine of the color steel tile press, the PLC computer control system, the hydraulic pump station system, the automatic shearing system Equipment features: the color steel plate equipment adopts high-level automatic control software, and the color steel tile press realizes the information management of production.

The automation control system of the whole unit adopts a highly integrated network, which makes the automation system function more superior.

The cold roll forming machine is the equipment for continuously processing metal sheets of a coil, a strip, by a multi-pas forming roller which is a plastic processing process to form a specific section profile.

Tangshan Shuoen Machinery is a professional forming machine manufacturer and exporter of all kinds of standard and nonstandard roll forming machinery.We offer various sheet metal and coil metal roll forming machines such as shelf and roll forming machines,downspout roll forming machines, double layer roll forming machines,roof sheeting machine,and manual corrugated iron roller for sale with the reliable process, high productivity, high reliability.

Our roll forming equipment consists of decolier machine,feeding table, guiding equipment, roll forming system, post-cutting system (electric o hydraulic, controlling system and hydraulic station. Wide variety of cold-formed steel, from the sub-section shape, with open, semi-closed and closed, the main products of roll forming machine are cold-formed channel steel angle steel, Z section steel, cold-formed corrugated steel, pipe, square tube,rectangular tube, welded tube-shaped,rolling shutter doors and so on. Steel cross-section shape can be designed: size, accuracy, and length can flexibly be adjusted according to need, all supplied by length or double length, improve material utilization, Production processes can also be matched with the punch, so as to meet different requirements.

For comprehensive solutions in roofing sheet rollingforming machine, please contact Shuoen Machinery via email at admin@tsshuoen.com or WhatsApp at (+86) 19331572740 for immediate assistance!