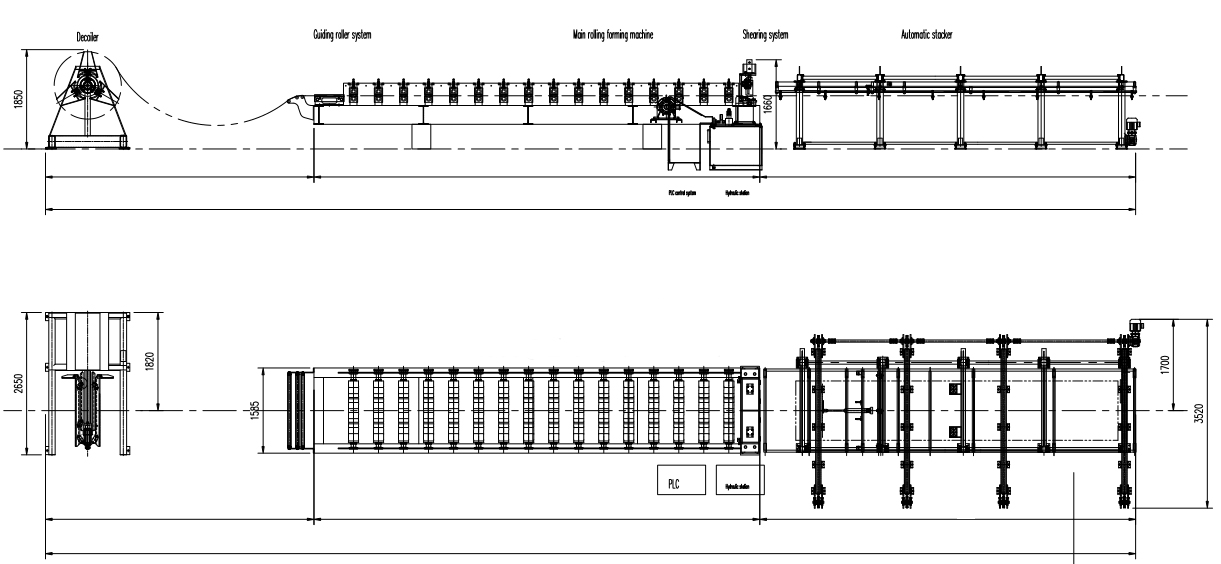

Type: Floor Deck Roll Forming Machine

Raw material:Galvanized coils

Feeding width:1250mm

Forming speed:0-15 m per minute

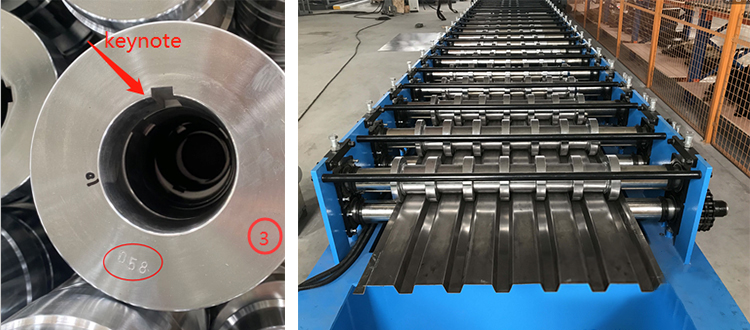

Forming stations:28 roller stations

Dimension(L*W*H): 15000 х 1850 х 1500 mm

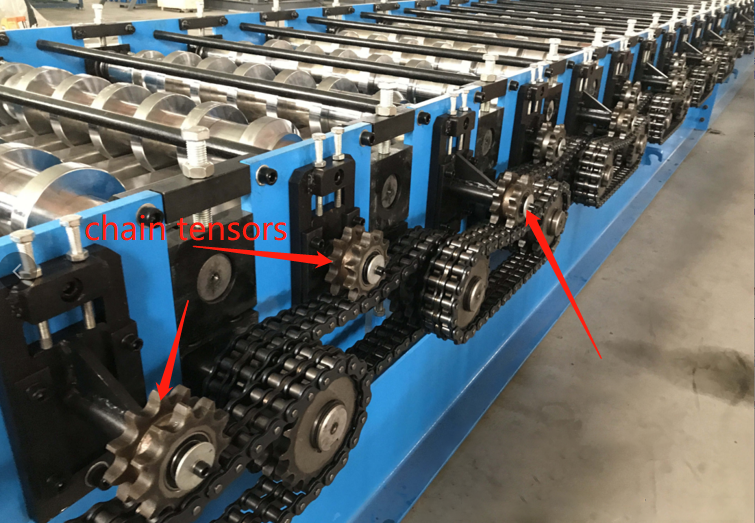

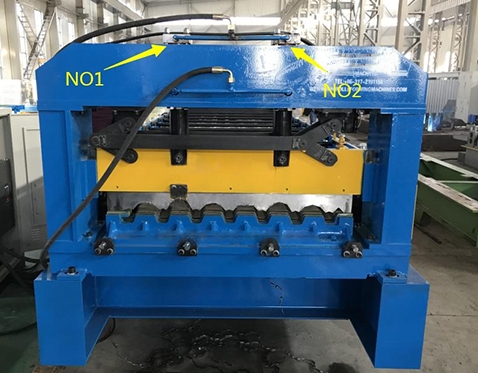

Core Components:Pressure vessel, Motor, Other, Bearing, Gear, Pump, Gearbox, Engine, PLC

Weight (KG): 1550 kg

Warranty: 1 years

Our machine has a long service life, simple operation and easy to use, we provide network

after-sales service for life. A strong behind-the-scenes team makes your purchase worry-free.

![]()

Techinical Parameter of block making machines

![]()

![]()

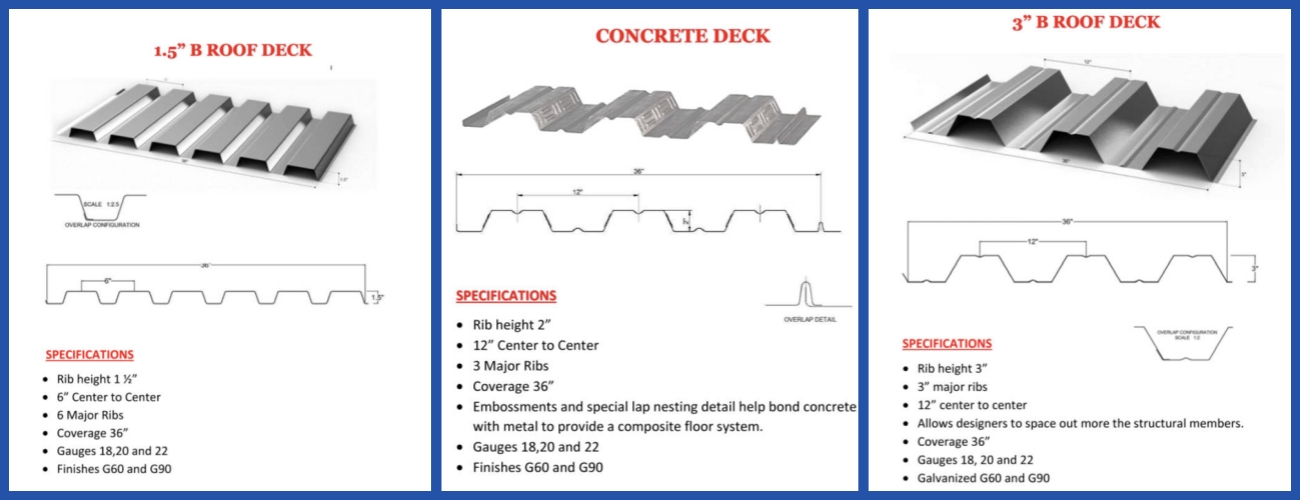

·Hot selling tile type

![]()

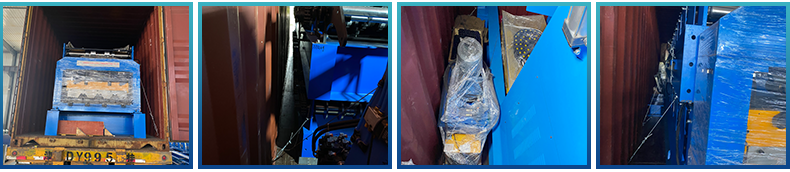

Selling Units:Single item

Package Type: seaworthy package

![]()

![]()

1.How about the quality of machines?

Our machines adopt advanced technology. Moreover, we carry out strict supervision during production and

make sure every finished product with high quality.

The advance deposit paid by T / T is 30%, and the balance before t / T loading is 70%. You can also choose other

trading methods.

Auto concrete brick making machine, Auto hydraulic brick making machine, Free pallet automatic block forming

machine,concrete,mixer, Batching machine, Stacker, Cuber, etc.