Type: Tile Forming Machine

Control system: PLC Control

Weight: 4.5 ton

Dimension(L*W*H):5900mm*1500mm*1200mm

Warranty: 2 years

Feeding width: 1220mm

Rolling thinckness: 0.3-0.8mm

Cutting blade material: Cr 12 High Grade Steel

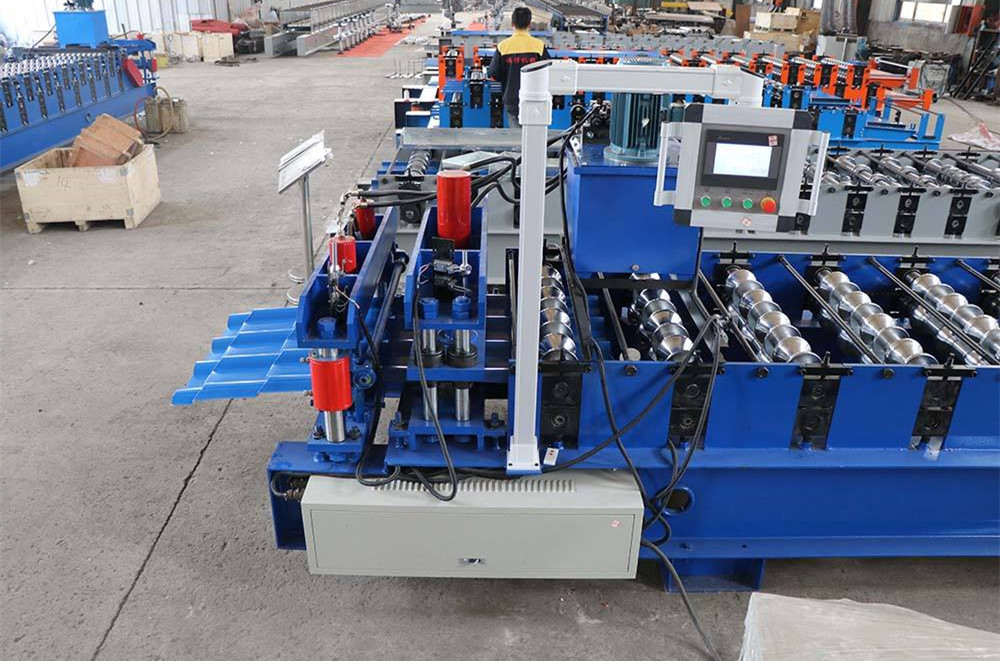

Double layer roofing sheet roll forming machine

Our machine has a long service life, simple operation and easy to use, we provide network

after-sales service for life. A strong behind-the-scenes team makes your purchase worry-free.

![]()

Product Name | Double deck roofing sheet roll forming machine |

Base material | GI. GL. PPGI. PPGL . Aluminum |

Thickness | 0.3mm-0.8mm (Customized) |

Effective Width | 762+686mm (Customized) |

Roll Forming machine Components Details | |

Size | 6050*1500*1600mm |

Weight | 5.5Tons |

Frame Material | 350H Steel(Customized) |

Side Panel Of Machine | 16mm(Customized) |

Color | All colors(standard international color)or (Customized) |

Rollers | UP: 13 roller Down: 18 roller |

Roller material | 45# steel Cr12 Mov HRC 58-62 |

Diameter Of The Shaft | Φ70mm |

Drive Mode | Chain Wheel and Cycle Chain Length:1 Inch |

Productivity | 10-15m/min |

Roll Forming machine Electric Components | |

Voltage | 380V 50Hz 3phases(Can be customized according to local voltage) |

Motor power | 5.5KW |

Cutting&Hydraulic | Hydraulic pump station : 4KW Regular Brand: LI CHAO (Customized) Type: Double guide pillar Hydraulic Cutting Blade: Cr12 Mov HRC 58-62 |

Control System | PLC Electronic control cabinet |

Screen | Button Control system with multiple languages |

Feature | Famous Brand, Multi-Purpose, Easy to Operation, Full Automatic Computer Control, long Service Life |

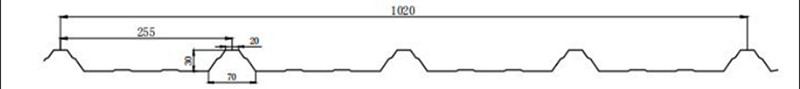

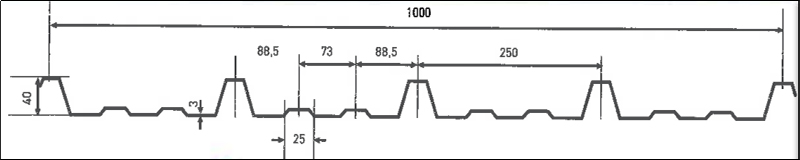

· Model Drawing

Upper Layer

Double Layer

![]()

Name:Feeding table

1.Function:Put the sheet into the machine

2.Benefits:Can ensure the sheet smooth and flat

3.Hand knife:Can save material

Name:Feeding table

1.Function:Put the sheet into the machine

2.Benefits:Can ensure the sheet smooth and flat

3.Hand knife:Can save material

Name: Main rollers

1.Material:45#High carbon steel

2.It is forged, polished, heat-treated and finally chromeplated.

The wheel is smooth and hard,do not scratch the sheet material.

Name:Computer Control Cabinet

1.Brand:LICHAO,DELTA,SIEMENS.(According to customers inquirement)

2.Opreation language: English/Russsian/Spanish/ Chinese

Name :Hydraulic station power

Hydraulic station power: 4Kw

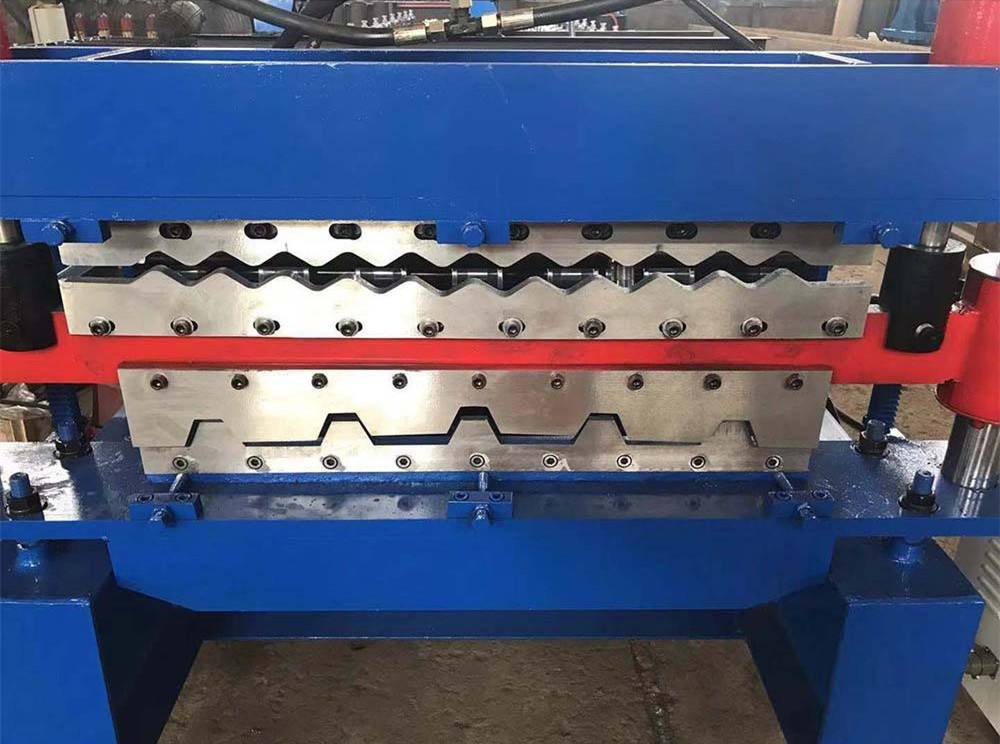

Name: Cutting head The blade is cut by laser

1.Material is Cr12 mov.16mm Double guide post+hydraulic drive

2.Guide post:45#steel Quenching is done before heat treatment,

can guarantee the surface smoothness and hardness.

![]()

![]()

- 1.Nude,with waterproof cloth and stow-wood.Imported computer control system packed with waterproof cloth and card board.

- 2.This producing line is maintained free of charge for 12 months.When the machine is used in China,we will install and debug

the machine for free;if it is used at abroad,we will send the professional technician to debug.Buyers should take all the fees for

technicians travelling abroad.

- 3.All the parts in the roll forming machine is free to maintain all the life,if in 24 months our company bear the cost for exchanged

the broken part like the new parts cost and express cost,if more than 24 month,we also free to maintain the broken parts ,but for

send the new parts,the buyer need bear the express cost.

- 4.When ship the roll forming machine,We will also send one set CD and specification(Chinese and English) to you with the

machine,they can teach you how to operater the machines.

![]()

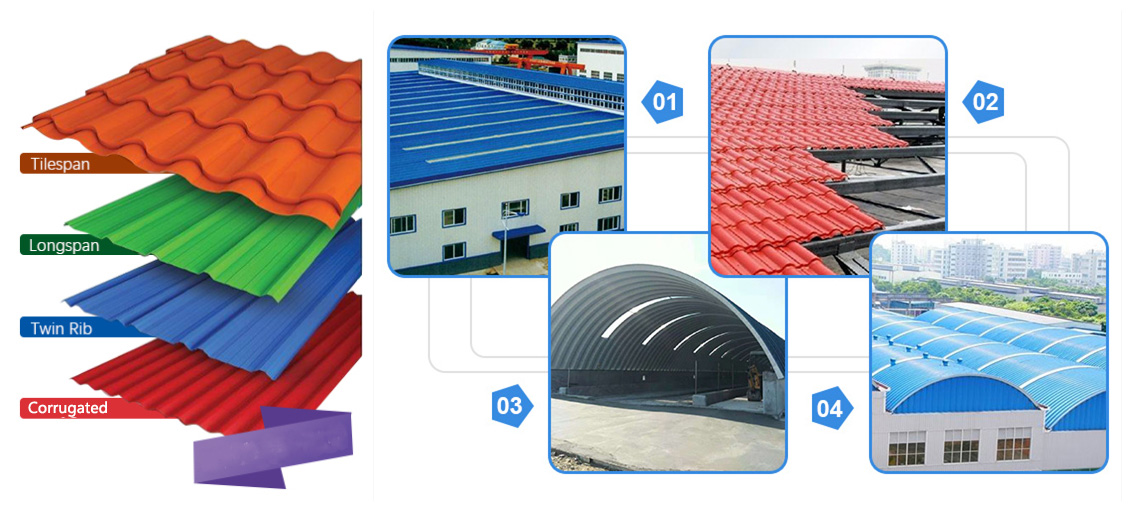

· Relative Raw Material

![]()

![]()

Q:What service can you provide before order?

A:About the pre-sale service, We provide professional solutions according your demands,such as design、

technical parameter, delivery flow etc. at the same time, we can supply invitation letter for your visit our factory

and know more our factory.

Q:Can you be responsible for transport?

A:Yes,we owned expert export team, we can arrangement for you to your destination port or address.

Q:Do you have after sales support?

A:Our engineer can supply remote-video technical support and teach your worker.

Q:How many workers is needed for the machine operation?

A:One worker is engough, the machine use automatic PLC control system.

Q:What's the warrany for our machine?

A:We provide 2years guarantee and provide lifetime technical support.

Q:If you can accept OEM? Design and manufacture according our photo.

A:Yes, we can accept OEM,we owned expert engineer team, and use famous brand components according

your demands.