Machine Type: Hexagonal wire mesh machine

Wire Diameter: 0.4 - 2 mm

Mesh width: 3300mm

Mesh size: 1/2' 1' 2' 3'

Working speed: 80-220m/hTwisting number: 3 Twist

Twisting number: 3

Power: 13kW

Weight: 4.2T

Warranty: 1 Year

Video outgoing-inspection: Provided

After Warranty Service: Video technical support, Online support, Field maintenance

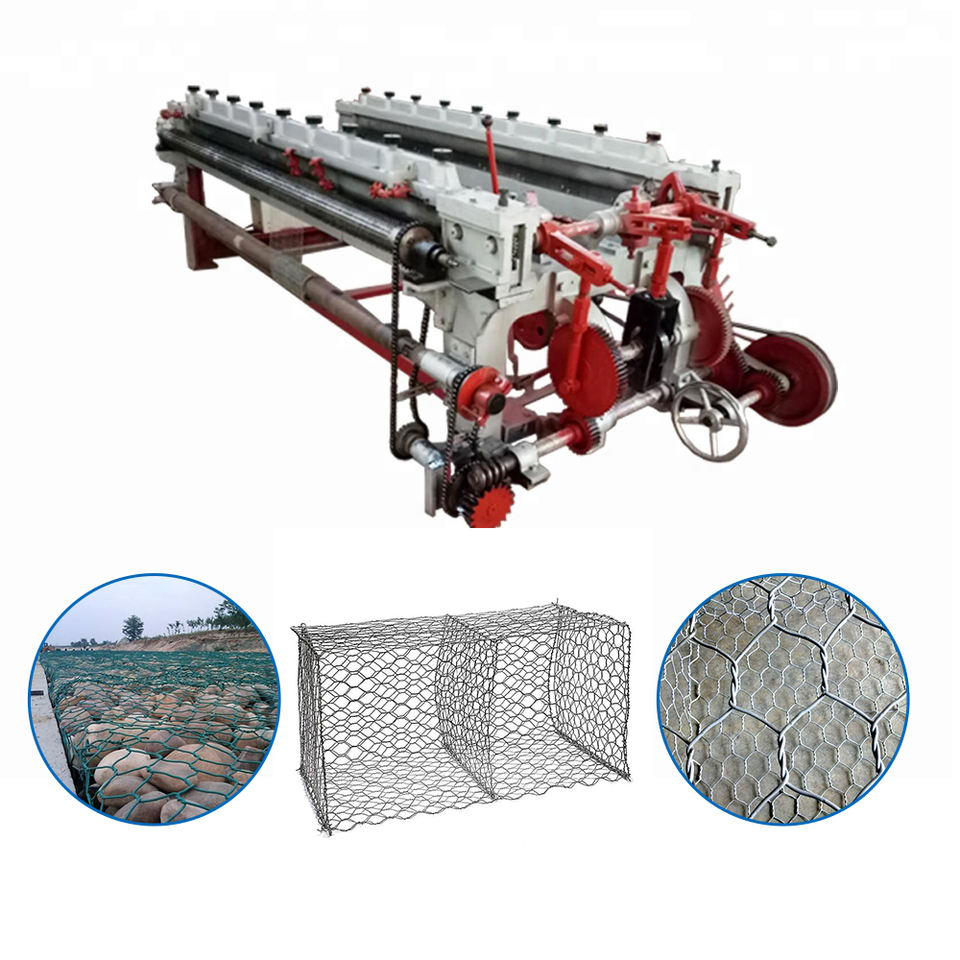

Hexagonal mesh machine, also named chicken mesh machine, is the special equipment to produce the

hexagonal wire netting mesh.

This machine adopts the principle of clockwise and counterclockwise twisting. Our factory produce the

straight and reverse twisted hexagonal wire netting machine with the models such as 1/2",3/4",1/2"1",2",

3",4" and so on.

![]()

| Raw material | Galvanized steel wire, PVC coated wire, stainless steel wire | ||||

| Wire diameter | 0.4-0.9mm | 0.4-1mm | 0.55-1.1mm | 0.7-1.7mm | 0.7-2.0mm |

| Mesh size | 1/2' | 3/4' | 1' | 2' | 3' |

| Mesh width | 2600mm | 3300mm | 3300mm | 3300mm | 3300mm |

| Working speed | 80-100m/h | 90-220m/h | 100-120m/h | 160-180m/h | 190-220m/h |

| Motor | 10.5KW | 10.5KW | 10.5KW | 10.5KW | 10.5KW |

| Working Dimension | 6.5*3.3*1.6M | 6.5*4.5*1.6M | 6.5*4.3*1.6M | 6.5*4.3*1.6M | 6.5*4.3*1.6M |

| Machine Weoght | 3T | 3.5T | 3.2T | 3.4T | 3.4T |

Note: 1. One hexagonal mesh machine can only make one hole size. 2. Special hole size can be customized as your request. | |||||

![]()

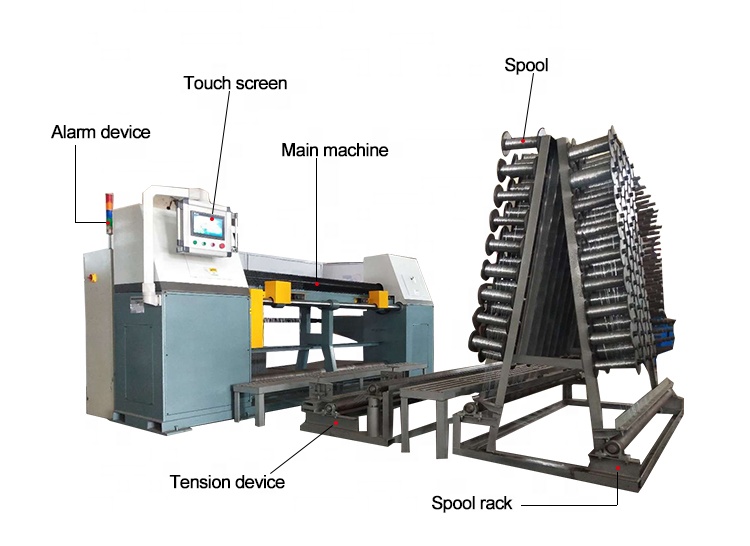

1.PLC control and touch screen.More technical parameters can be set and adjusted on the touch screen.

Very convenient for workers to operate.

2.More accurate,Less Wire and mesh broken.Once wire or mesh broken,alarm will reflect and machine will

stop automatically.

3.Lubricating system makes the machine to work more easily.

4.Speed more fast and production capacity imporved more.

· Relative Raw Material

![]()

Hexagonal wire netting is manufactured in-galvanized iron and galvanized iron drawn wire. It is extensively

used in building as reinforcement of the roof and floor, light. Fencing for poultry farms, birds cages.

Tennis courts and fish garden, and children playground.

![]()

- 1.Nude,with waterproof cloth and stow-wood.Imported computer control system packed with waterproof cloth and card board.

- 2.This producing line is maintained free of charge for 12 months.When the machine is used in China,we will install and debug

the machine for free;if it is used at abroad,we will send the professional technician to debug.Buyers should take all the fees for

technicians travelling abroad.

- 3.All the parts in the roll forming machine is free to maintain all the life,if in 24 months our company bear the cost for exchanged

the broken part like the new parts cost and express cost,if more than 24 month,we also free to maintain the broken parts ,but for

send the new parts,the buyer need bear the express cost.

- 4.When ship the roll forming machine,We will also send one set CD and specification(Chinese and English) to you with the

machine,they can teach you how to operater the machines.

![]()

Q:What service can you provide before order?

A:About the pre-sale service, We provide professional solutions according your demands,such as design、

technical parameter, delivery flow etc. at the same time, we can supply invitation letter for your visit our factory

and know more our factory.

Q:Can you be responsible for transport?

A:Yes,we owned expert export team, we can arrangement for you to your destination port or address.

Q:Do you have after sales support?

A:Our engineer can supply remote-video technical support and teach your worker.

Q:How many workers is needed for the machine operation?

A:One worker is engough, the machine use automatic PLC control system.

Q:What's the warrany for our machine?

A:We provide 2years guarantee and provide lifetime technical support.

Q:If you can accept OEM? Design and manufacture according our photo.

A:Yes, we can accept OEM,we owned expert engineer team, and use famous brand components according

your demands.