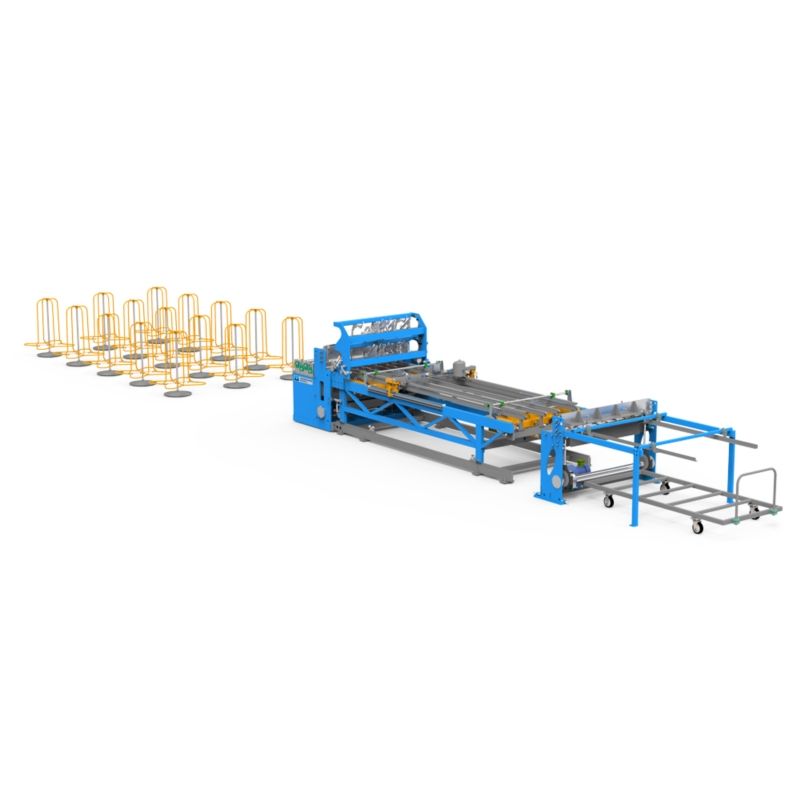

Machine Type:cage welding machine

Mesh width: 1.2-1.6m

Line wire pitch: 50-300mm

Cross wire pitch: 20mm

Wire diameters: 2.0--3.5mm

Welding Speed: 120tims/min

Weight : 3.6ton

Warranty: 1 Year

Video outgoing-inspection: Provided

After Warranty Service: Video technical support, Online support, Field maintenance

This is our new developed chicken cage welding machine SE-AW-1200H (Pneumatic type). The welding speed can be up to a maximum of 130 times/min. It has the advantage of easier machine maintenance, fewer machine problems, easier to learn and operate, save power and consumption, less welding spark, etc. We also have mechanical type machine, the model is SE-AW-1200E.

![]()

| Model | SE-AW-1200H | SE-AW-1500H | SE-AW-1600H |

| Wire diameter | 2-3.5mm/2-4mm | ||

| Longitude wire space | Mostly 50-200mm(If min.25*25mm, we can also design.) | ||

| Crosswire space | Min.25mm or smaller (PLC control) | ||

| Mesh width | Max.1200mm | Max.1500mm | Max.1600mm |

| Welding electrodes | 25pcs | 32pcs | 32pcs |

| Welding transformer | 125kva*3pcs | 125kva*4pcs | 125kva*4pcs |

| Longitude wire feeding | Form wire coils | ||

| Crosswire feeding | Pre-straightened&pre-cut(cross wire feeder) | ||

| Welding speed | Max.130 times/min | ||

| Space needed | 12*5m | ||

| Machine weight | 3100kg | 3600kg | 3840kg |

![]()

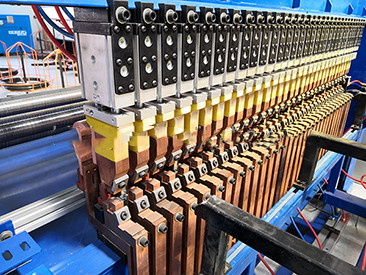

| Pneumatic welding, each welding electrode is controlled by one SMC air cylinder. Electrodes 20*20*20mm can be used 6 sides. |

Double cross wire feeders, can feed different lengths of cross wires. You can also choose a single cross wire feeder. The feeding speed can max .130pcs/min. |  |

| The edge cutter is controlled by two big SMC brand air cylinders on two sides, the cutting speed can match the welding speed. |

Panasonic servo motor for pulling mesh, cross wire space can be adjusted by PLC. The pulling rack is the J&T brand, more accurate, less noise. |  |

| The mesh cutting is automatic, max.3m length. After cutting, the mesh can fall down automatically to the mesh stacking car. |

· Auxiliary Equipments

1. The cage bending machine is used to bend the top cage mesh and bottom cage mesh.

2. The edge cuttter is used to cut the extra wires of the mesh side.

3. The door cutting machine is used to cut the insider wires of the cage mesh to make a door.

4. C -ring tool is used to connect the bottom cage mesh, top cage mesh, and partition mesh.

5. The electric cutter is used to cut the mesh manually.

6. The spot welding machine is used to weld the partition mesh, single spot or multi spots.

7. Wire straightening and cutting machine is used to straight and cut the wires.

· Relive Raw Material

![]()

![]()

- 1.Nude,with waterproof cloth and stow-wood.Imported computer control system packed with waterproof cloth and card board.

- 2.This producing line is maintained free of charge for 12 months.When the machine is used in China,we will install and debug

the machine for free;if it is used at abroad,we will send the professional technician to debug.Buyers should take all the fees for

technicians travelling abroad.

- 3.All the parts in the roll forming machine is free to maintain all the life,if in 24 months our company bear the cost for exchanged

the broken part like the new parts cost and express cost,if more than 24 month,we also free to maintain the broken parts ,but for

send the new parts,the buyer need bear the express cost.

- 4.When ship the roll forming machine,We will also send one set CD and specification(Chinese and English) to you with the

machine,they can teach you how to operater the machines.

![]()

Q:What service can you provide before order?

A:About the pre-sale service, We provide professional solutions according your demands,such as design、

technical parameter, delivery flow etc. at the same time, we can supply invitation letter for your visit our factory

and know more our factory.

Q:Can you be responsible for transport?

A:Yes,we owned expert export team, we can arrangement for you to your destination port or address.

Q:Do you have after sales support?

A:Our engineer can supply remote-video technical support and teach your worker.

Q:How many workers is needed for the machine operation?

A:One worker is engough, the machine use automatic PLC control system.

Q:What's the warrany for our machine?

A:We provide 2years guarantee and provide lifetime technical support.

Q:If you can accept OEM? Design and manufacture according our photo.

A:Yes, we can accept OEM,we owned expert engineer team, and use famous brand components according

your demands.