Machine Type: panel fence welding machine`

Wire diameter: 2.5-6mm

Mesh width: 1-3M

Mesh length: 0.8-3.5m

Welding Speed: 80 times/min

Mesh size: 50*100/50*75mm

Voltage: 380/50HZ /Customzied

Weight: 4T

Warranty: 1 Year

Video outgoing-inspection: Provided

After Warranty Service: Video technical support, Online support, Field maintenance

Welded mesh panel machine can produce road fence, beside that can produce kinds of reinforce

mesh for road, building, brige, coalmine,and so on, also can produce cage to feeding animal.

![]()

You can send your requirement to us, we can design the machine as you wish!

| Type1 | Type2 | Type3 | |

| mesh size | 50*50--200*200mm | 100*100--300*300mm | 100*100--300*300mm |

| width | 2000mm | 2000mm | 2000mm |

| motor | 5.5KW | 5.5kw | 5.5kw |

| transformer | 120KVA*4 | 160KVA*4 | 200KVA*4 |

| speed | 60rows/min | 50 rows/min | 40 rows/min |

| spare machine | wire straighten and cutting machine(2.5-6mm,two sets), | wire straighten and cutting machine(4-8mm two sets), | wire straighten and cutting machine(8-12mm two sets), |

1)Main welding machine:Speed:100times/min.Our welding machine adopts pneumatic pressure system ,

which ensure the welding points more firm than mechanical system.

2) Our line wire feeding is from pre-cut,as so the finished mesh panel surface will be more flat than ling

wire feeding from coil.And the line wire length can reach max 4.5m

3) The cross hopper with a cross wire storage and automatic feeding device, storage capacity of about

1.5 tons, to reduce the manual reclaim material, improve production efficiency.The pushing power adopts

1.0KW servo motor.

4) The pulling system power is droven by the servo motor.The pulling system adopts the circle model, which

save the time and improve the welding speed.Another advantage is the pulling frame is moved, and it is

more convenient when the line wire spacing is adjusted.

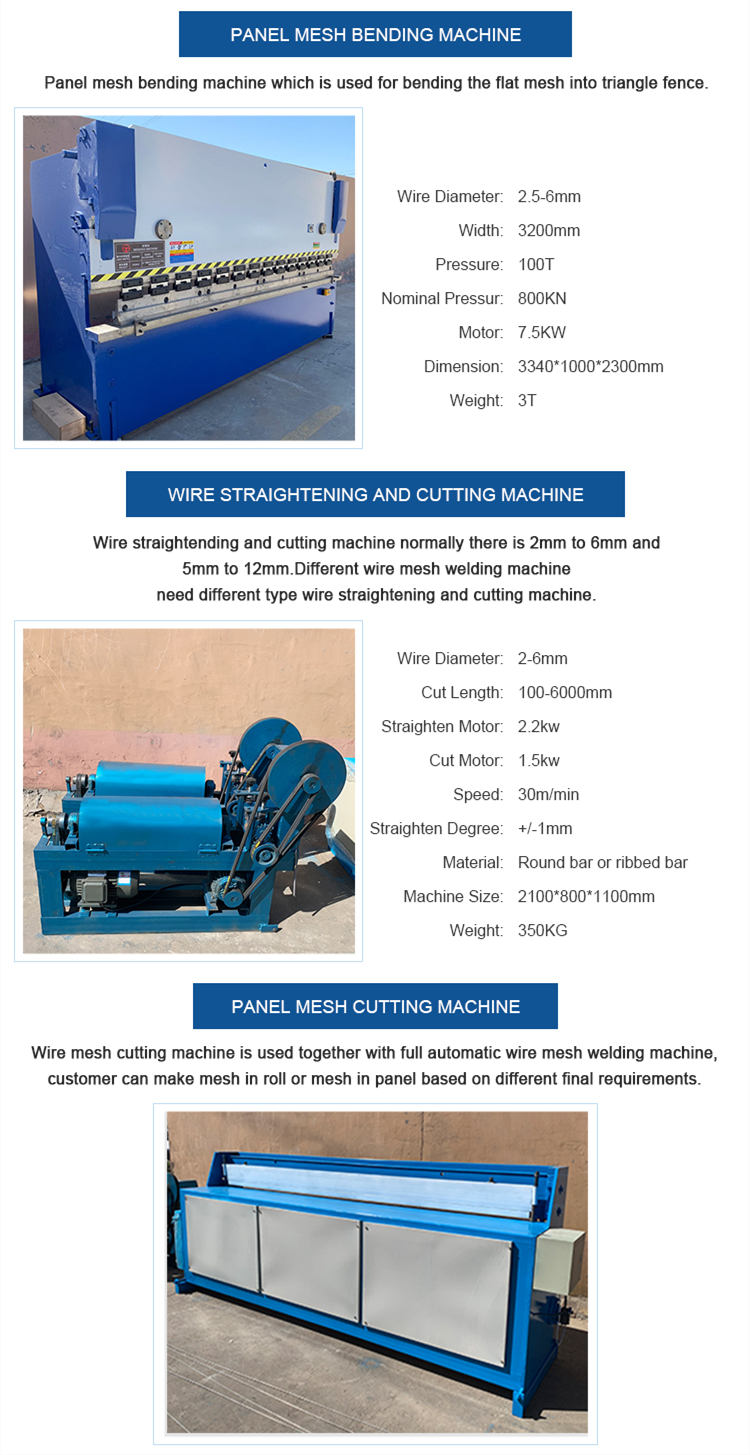

Auxiliary Equipments

![]()

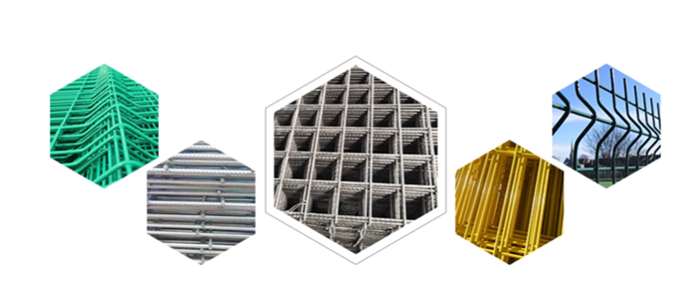

3D fence mesh purposes:mainly used in industrial,agricultural,prison,municipal,transportation and

other industries for fences,decoration,protection and other facilities.

![]()

- 1.Nude,with waterproof cloth and stow-wood.Imported computer control system packed with waterproof cloth and card board.

- 2.This producing line is maintained free of charge for 12 months.When the machine is used in China,we will install and debug

the machine for free;if it is used at abroad,we will send the professional technician to debug.Buyers should take all the fees for

technicians travelling abroad.

- 3.All the parts in the roll forming machine is free to maintain all the life,if in 24 months our company bear the cost for exchanged

the broken part like the new parts cost and express cost,if more than 24 month,we also free to maintain the broken parts ,but for

send the new parts,the buyer need bear the express cost.

- 4.When ship the roll forming machine,We will also send one set CD and specification(Chinese and English) to you with the

machine,they can teach you how to operater the machines.

![]()

· Relative Raw Material

![]()

![]()

Q:What service can you provide before order?

A:About the pre-sale service, We provide professional solutions according your demands,such as design、

technical parameter, delivery flow etc. at the same time, we can supply invitation letter for your visit our factory

and know more our factory.

Q:Can you be responsible for transport?

A:Yes,we owned expert export team, we can arrangement for you to your destination port or address.

Q:Do you have after sales support?

A:Our engineer can supply remote-video technical support and teach your worker.

Q:How many workers is needed for the machine operation?

A:One worker is engough, the machine use automatic PLC control system.

Q:What's the warrany for our machine?

A:We provide 2years guarantee and provide lifetime technical support.

Q:If you can accept OEM? Design and manufacture according our photo.

A:Yes, we can accept OEM,we owned expert engineer team, and use famous brand components according

your demands.